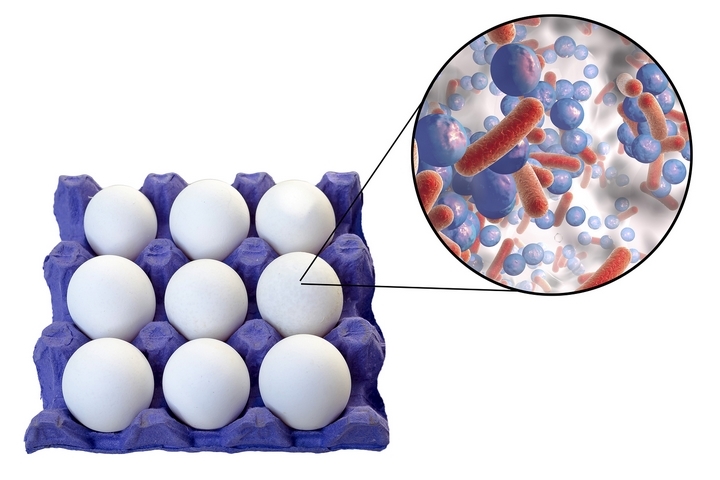

If you are a manufacturer of foods then you understand the importance of having food packaging that does not leak. Even the smallest leak in your food packaging can cause some very big problems for your ability to deliver the product that you need to and also can be very harmful for your reputation. This makes the testing of leaks in the food packaging that you use an essential step in the quality control process.

So, how do you ensure that there are no leaks in the food packaging that you’re going to be using? There are many leak detection equipment and methods available, each with their own benefits and practical applications. If you want to know more about how you can ensure that there are no leaks in your food packaging, read on.

1. Gas leak detection

This is a method that is very effective at finding very small holes in your packaging materials. This method of leak detection is used among a wide range of industries to check for airtight seals and joints. The gases that are used to find leaks are usually carbon monoxide, hydrogen and helium.

2. A dry chamber

This is most commonly used for beverage and liquid containers. The package that contains the liquid is placed into a chamber that is then set to a vacuum. The next step is to use an absorbent material to test if any of the liquid has escaped from the container. If any moisture is detected in the dry chamber then that means there is a leak in the package and it will need to be reviewed. As frustrating as it can be, catching a defect in the packaging at this stage is preferable to discovering a problem after distribution.

3. Vacuum chamber

If you are planning to ship your food packaged via air then you need to make sure that they can survive the trip intact. When food packages are shipped via air they are often placed in the cargo hold which is unpressurized. For this reason, the packages need to be able to remain sealed when exposed to very low pressure. To test for this, the sealed food packaging is placed inside a vacuum chamber. If they pass this test then that is suitable for air travel and can be shipped on schedule.

4. Immersion testing

This is also a good way to test the packaging strength before it is transported via an airplane. To test food packaging through the immersion method the package is submerged in water and observed to see if there are any bubbles. If any bubbles are seen then it means that the package is not airtight and that it needs further development and testing before food can be transported this way.

5. The Ultrasonic Method

The food package is placed next to a source of ultrasonic waves. These waves are analyzed and an image is created for review. This method is not too dissimilar from an ultrasound scan that is performed by medical professionals. This can produce some very accurate results however you will need someone who is skilled at interpreting the results to make the determination of whether the package passes or fails.

6. Machine vision testing

This uses a camera that is connected to a computer that can search the food packaging for any defects or very small holes. If you are looking to use this method be sure to ask if it is fully up to date as the quality of the software used can vary a great deal.